Sheroz Earthworks for Beginners

Sheroz Earthworks for Beginners

Blog Article

The Single Strategy To Use For Sheroz Earthworks

Table of ContentsGetting The Sheroz Earthworks To WorkThe Ultimate Guide To Sheroz EarthworksWhat Does Sheroz Earthworks Do?The Basic Principles Of Sheroz Earthworks Some Known Facts About Sheroz Earthworks.The 9-Minute Rule for Sheroz Earthworks

Today, Smart Construction Remote attaches over 700 machines on jobsites to workplaces, conserving countless hours formerly spent by jobsite managers, land surveyors and engineers commuting from workplaces to jobsites. So to sum up, the first one decade of Komatsu's smart device control have been noted by a decade of unique innovation, constant discovering and development with customers.

Here's to the next 10 years! Material generated in organization with Komatsu.

In the rapidly advancing world of building, precision and efficiency are necessary. 3D device control, a system that uses general practitioner and various other sensors to direct machinery with pinpoint precision, is revolutionising the market - https://papaly.com/categories/share?id=2fb5cd080ed44e92a364571e3aef5522. From its very early days of 2D support, this technology has advanced substantially, making jobs that once required hand-operated intervention now possible with marginal human input

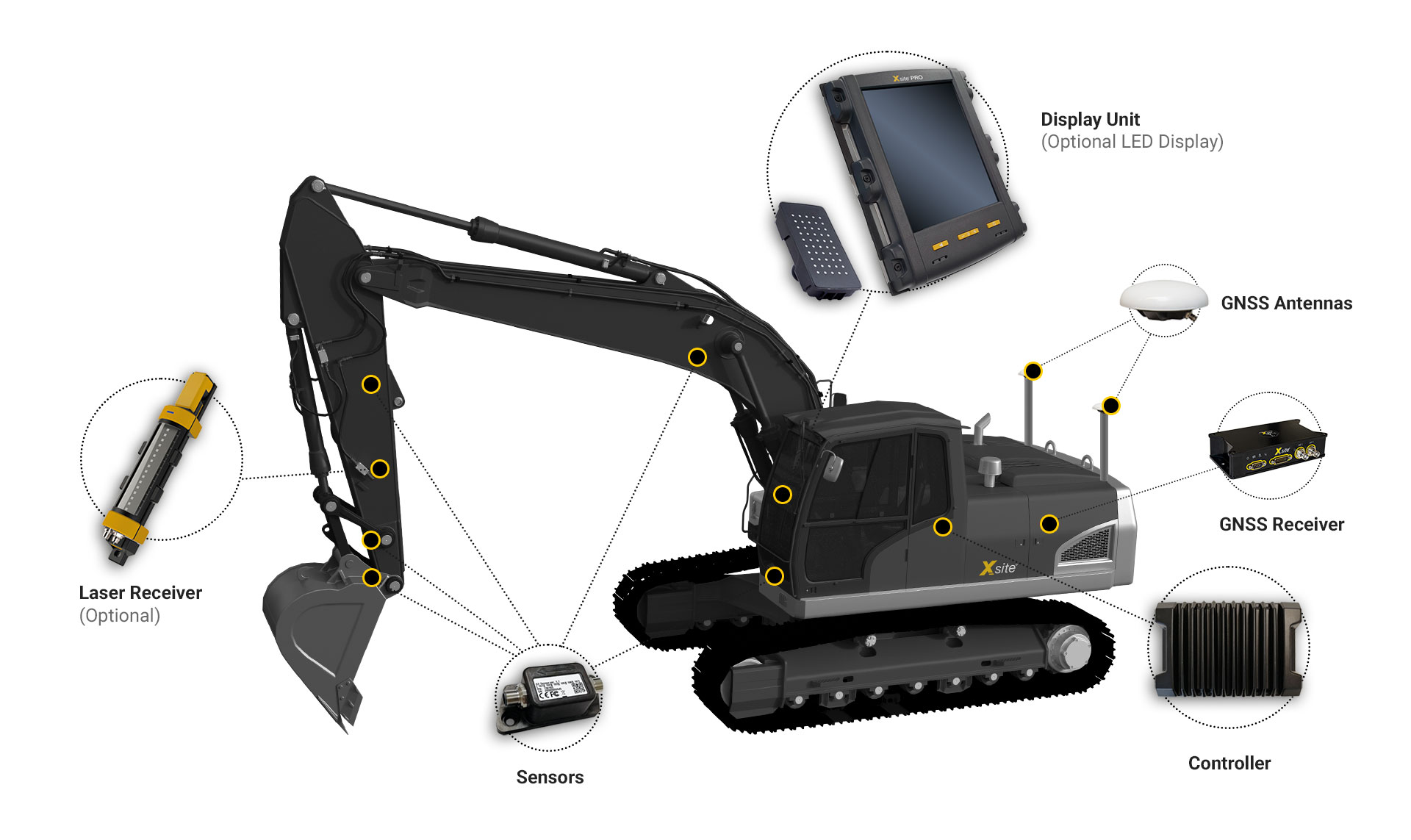

In building, it guarantees that every cut, fill, and grade is executed with medical accuracy. Let's explore how this game-changing innovation works. At the core of any kind of 3D maker control system are GNSS receivers and antennas, recording satellite signals to figure out the device's specific location. Onboard computer systems and control boxes procedure this data and interact with the equipment.

Some Known Factual Statements About Sheroz Earthworks

This includes setting up GNSS receivers, calibrating sensing units, and setting up the maker control software program - fj dynamics auto steer price. The magic of 3D equipment control lies in its real-time data collection and processing.

User interfaces offer real-time updates on the equipment's position and essential modifications, making certain precise control. In construction, 3D machine control is utilized for earthmoving, grading, paving, and excavation, guaranteeing tasks are finished to precise requirements.

What Does Sheroz Earthworks Do?

3D device control significantly raises performance by minimizing rework and reducing material waste, bring about quicker and much more economical job conclusion. The technology ensures every task is performed specifically as intended, resulting in constantly top notch job. One of the most engaging advantages of 3D device control is the substantial expense financial savings it uses.

Fuel usage is optimised because equipments operate extra efficiently and prevent unneeded motions. Maintenance prices are likewise reduced, as the equipment experiences less damage due to specific operation. Overall, these cost savings add to a more lucrative profits for any type of project. By reducing human mistake and limiting exposure to unsafe environments, 3D maker control improves employee security and reduces accidents.

From construction to mining, this technology ensures tasks are performed precisely and safely, reducing costs and improving end results. As innovations continue, the potential for 3D device control to further boost performance and security expands. Embracing this technology is vital for market experts wanting to remain affordable and achieve the highest possible standards in their projects.

10 Easy Facts About Sheroz Earthworks Shown

Discover the future of accuracy and efficiency now! Additionally, take a look at our newest YouTube video on the FJD H36 Electric Motor Grader Control System to see the technology at work: Watch currently.

Throughout the years, we have actually seen drivers with whole lots of experience do some amazing things with their makers. Possibly they have an eye for modifications that improve precision, or probably they know which attributes of their machine to make use of and when to increase efficiency or performance - https://www.video-bookmark.com/bookmark/6399293/sheroz-earthworks/. However with today's improvements in hefty tools innovation, even experienced operators can take advantage of a real-time help to improve their day-to-day efficiency he has a good point (fj dynamics autosteer review).

This is where device control systems aspect in. Some excavators come with equipment control systems that guide the operator with functions to automate the excavating procedure.

Getting The Sheroz Earthworks To Work

With this added accuracy, rework is basically removed, permitting the driver to finish the project on time and relocate to the following job. For those dealing with dangerous or hard jobsites, remote-controlled options open brand-new opportunities. This outstanding add-on permits you to run an excavator from a range in locations with harmful substances (like in a potash mine) or inadequate ground problems (like mud).

Machine control systems give beneficial advantages to more than simply excavator drivers. On-board weighing apps for wheel loaders, for example, are popular because numerous are so simple to utilize. On-board weighing makes quick job of precise filling. If you have a vehicle come in with a target of 23 tons, your operator can fill their container and dynamically consider itoften without even being fixed.

This suggests the operator can see the specific weight of the tons they're concerning to dispose (topcon gps). On-board considering offers real-time understanding into the container's lots to make overloading, underloading, reweighing and waiting times a thing of the past. Volvo Building EquipmentIf they unload 12 lots on the very first pass, the following container requires to consider 11 loads

The Buzz on Sheroz Earthworks

Most procedures utilize an on-board considering app to ensure that the load is exact prior to they send their trucks to the scales, which is essential due to the fact that the scale weight is what's used for invoicing and invoicing purposes. A number of manufacturers consist of some kind of considering program on their loaders. Some also have features that permit companies to keep an eye on and control the total tons of multiple trucks.

Report this page